Program Overview

The mission of the State Superfund Unit is to protect the public health and welfare of all Montana citizens and the state's environment from releases of hazardous or deleterious substances.

State Superfund Unit's Focus

Facilitating the investigation and cleanup of hazardous substances that typically occur at sites with the following activities: mining, petroleum refining, railroad fueling and maintenance, smelting, and wood treating.

State Superfund Unit's Purpose

- Protect human health and the environment

- Prevent exposure of human and ecological receptors to hazardous or deleterious substances released to air, groundwater, soil, sediment, or surface water

- Ensure compliance with applicable state and federal regulations

The State Superfund Unit ranks release sites based on potential risks to public health and the environment using the Priority Ranking Sheet. Site investigation and cleanup activities focus primarily on sites which have a maximum or high priority rank.

Programs

What Is CECRA?

The State Superfund Unit utilizes the Comprehensive Environmental Cleanup and Responsibility Act (CECRA) and the Environmental Quality Protection Fund (EQPF) to investigate and cleanup hazardous substances at sites not addressed by federal Superfund. Historical waste disposal activities at these sites caused contamination of air, surface water, groundwater, sediments, and/or soils with hazardous or deleterious substances. Under CECRA, sites are ranked based on potential risks to human health and the environment.

The Comprehensive Environmental Cleanup and Responsibility Act (CECRA) defines “Facility” as all areas where a hazardous or deleterious substance has been deposited, stored, disposed of, placed, or otherwise come to be located (§75-10-701(4), MCA).

CECRA Statute and Rules

The act is contained in §§ 75-10-701 through 752, MCA. The associated rules are contained in ARM 17.55.101 through ARM 17.55.115.

CECRA History

The 1985 Montana Legislature passed the Environmental Quality Protection Fund Act. This Act created a legal mechanism for the Department to investigate and clean up, or require liable persons to investigate and clean up, hazardous or deleterious substance facilities in Montana. The 1985 Act also established the Environmental Quality Protection Fund (EQPF). The EQPF is a revolving fund in which all penalties and costs recovered pursuant to the EQPF Act are deposited. The EQPF can be used only to fund activities relating to the release of a hazardous or deleterious substance. Although the 1985 Act established the EQPF, it did not provide a funding mechanism for the Department to administer the Act. Therefore, no activities were conducted under this Act until 1987.

The 1987 Montana Legislature passed a bill creating a delayed funding mechanism that appropriated 4 percent of the Resource Indemnity Trust (RIT) interest money for Department activities at non-National Priority List facilities beginning in July 1989 (§ 15-38-202 MCA). In October 1987, the Department began addressing state Superfund facilities. Temporary grant funding was used between 1987 and 1989 to clean up two facilities and rank approximately 250 other facilities. Beginning in fiscal year 1995, the 4 percent allocation was changed to 6 percent to adjust for other legislative changes in RIT allocations. Effective July 1, 1999, the 6 percent allocation was increased to 9 percent.

The 1989 Montana Legislature significantly amended the Act, changing its name to the Montana Comprehensive Environmental Cleanup and Responsibility Act (CECRA; contained in Sections 75-10-701 through 752, MCA) and providing the Department with similar authorities as provided under the federal Superfund Act (CERCLA). With the passage of CECRA, the state Superfund program became the CECRA Program. Major revisions to CECRA did not occur until the 1995 Legislature, when the Voluntary Cleanup and Redevelopment Act (VCRA; contained in Section 75-10-730 through 738, MCA), a mixed-funding pilot program, and a requirement to conduct a collaborative study on alternative liability schemes were added and provisions related to remedy selection were changed. Based on the results of the collaborative study, the 1997 Legislature adopted the Controlled Allocation of Liability Act (CALA; contained in Section 75-10-742 through 751, MCA), which provides a voluntary process for the apportionment of liability at CECRA facilities and establishes an orphan share fund. Minor revisions to CECRA have been made by the 1999, 2001, 2003, 2005, 2007, 2009, 2011, 2013, 2015, and 2019 Legislatures.

CECRA Priority List

The CECRA Priority List is updated semi-annually as required in ARM 17.55.105. The CECRA Priority List is available in three formats:

- CECRA Priority List organized by Site in pdf format.

- CECRA Priority List organized by City in pdf format.

- CECRA Priority List organized by County in pdf format.

The CECRA Process

State Superfund Process Flowchart

Prioritize & Initial Investigation:

DEQ evaluates sites where hazardous or deleterious substances may have been released and determines the priority for further action. Some sites may go through the federal superfund site process for initial investigation to determine if contamination is present at levels that require additional evaluation and if the site has the potential to be a federal superfund site. Only a few sites go on to become federal superfund sites and some that could be federal sites remain state superfund sites. The remaining sites follow the process below.

Identify & Notify:

Some sites are cleaned up through the voluntary cleanup program if the cleanup can be completed in five years. At other sites, DEQ conducts a good faith investigation to identify the persons responsible for investigating and cleaning up a contaminated site. This typically includes deed and record searches, seeking information from people that worked at or owned/operated a site, and reviewing historical documents to determine when and how contamination occurred. Then DEQ officially informs the person that they are responsible and offers the person the opportunity to properly and expeditiously conduct the necessary work. If the person fails to conduct the work, DEQ may order the person to do the work.

3-Step Investigation:

This process is used to determine if and how a site needs to be cleaned up. The responsible person completes these steps. A remedial investigation is performed to determine the full nature and extent of the contamination. A risk assessment evaluates the threats posed to human health and the environment and allows for the development of site-specific cleanup levels. Finally, a feasibility study evaluates the various options for cleaning up the site. DEQ uses this information to determine if a site needs to be cleaned up, and if so, how it should be done. Interim actions may be conducted at any time during this process (as long as they would not interfere with final cleanup) to quickly reduce the amount of contamination and protect public health.

1. Determining the Final Cleanup:

DEQ prepares a proposed plan to outline the preferred cleanup option for the site. The public has the opportunity to comment on the preferred cleanup option. DEQ considers the comments and may revise the final cleanup based upon public comment. DEQ’s determination of the final cleanup for a site is documented in its record of decision.

2. Implementing the Final Cleanup:

Typically, DEQ and the responsible person negotiate a consent decree or order to implement the cleanup. Engineering design documents are completed and the project is bid. Cleanup continues until contamination no longer poses an unacceptable risk to human health and the environment and compliance with all environmental laws is achieved. The final cleanup is documented in a remedial action report.

3. No Further Action/Delisting:

Once DEQ determines that all cleanup criteria are met at a site, a no further action letter is issued and the site may be delisted, if appropriate.

What Is VCRA?

The act was developed to permit and encourage voluntary cleanup of facilities where releases or threatened releases of hazardous or deleterious substances exist, by providing interested persons with a method of determining what the cleanup responsibilities will be for reuse or redevelopment of existing facilities. Any entity (such as facility owners, operators, or prospective purchasers) may submit an application for approval of a voluntary cleanup plan (VCP) to the Department. VCPs may be submitted for facilities whether or not they are on the CECRA Priority List (see CECRA information above).

The VCP consists of two components. The first is the submission of an environmental assessment of the facility. Once the Department determines that the environmental assessment component of the VCP for the facility is complete, the VCRA applicant may submit the cleanup or remediation proposal component of the VCP to the Department. After the Department determines the remediation proposal is complete, both components of the VCP are submitted for public comment and DEQ approval. The environmental assessment component requires the written consent of current owners of the facility or property to access the facility/property for sampling/investigation purposes and the remediation proposal component requires the written consent of current owners of the facility or property to implementation of the VCP and access to the facility/property.

VCRA Legislation

The act is contained in §§ 75-10-730 through 738, MCA. Major sections include: § 75-10-732 - eligibility requirements; § 75-10-733 and § 75-10-734 - environmental property assessment and remediation proposal requirements; § 75-10-735 - public participation; § 75-10-736 - timeframes and procedures for Department approval/disapproval; and § 75-10-738 - closure process. Section 75-10-721, MCA of CECRA must also be met.

VCRA History

The 1995 Montana Legislature originally amended the Comprehensive Environmental Cleanup and Responsibility Act (CECRA; contained in Sections 75-10-705 through 729, MCA), creating the Voluntary Cleanup and Redevelopment Act (VCRA; contained in Sections 75-10-730 through 738, MCA). VCRA formalizes the voluntary cleanup process in the state. It specifies application requirements, voluntary cleanup plan requirements, agency review criteria and time frames, and conditions for and contents of no further action letters. The 2009 Montana Legislature modified the statute to divide VCPs into two components: an environmental assessment and a remediation proposal. The 2019 Montana Legislature modified the statute regarding the timing for property owners' consent for implementation of cleanup, and also to allow more time to complete groundwater cleanups under VCRA.

The VCRA Process

The act offers several incentives to parties that voluntarily perform cleanup. Any entity can apply, and liability protection is provided to entities that would otherwise not be responsible for site cleanup. Cleanup can occur on an entire facility or a portion of a facility. Under this act, the Department cannot take enforcement action against the party conducting an approved voluntary cleanup for work addressed in that plan. The Department's review process is streamlined so that each component of a VCP is reviewed for completeness within 30 days. Once the Department determines both components of an application are complete, it must decide within 60 days (which includes a 30-day public comment period) whether to approve or disapprove of the application. The Department's decision is based on the proposed uses of the facility identified by the applicant and any risk evaluation completed by the VCP applicant. Once a plan has been successfully implemented and Department costs have been paid, the applicant can petition the Department for closure. The Department must determine whether closure conditions are met within 60 days of this petition and, if so, the Department will issue a closure letter for the facility (if the entire facility was addressed in the VCP-remediation proposal) or the portion of the facility addressed by the VCP-remediation proposal. The Department may not approve a VCP that would take longer than 60 months to complete (120 months to complete for groundwater remediation) after DEQ approval, except for the period necessary for the operations and maintenance of the approved remediation proposal.

Other VCRA Information

The Department does not currently have a memorandum of agreement (MOA) with the Environmental Protection Agency (EPA) for its Voluntary Cleanup Program.

The Department has produced a VCRA Application Guide to assist applicants in preparing the environmental assessment and remediation proposal components of the VCP application; this guide is not a regulation and adherence to it is not mandatory.

The links below provide the 2020 VCRA Guide as a complete compiled version, as well as the associated VCRA process figure and attachments as stand-alone versions for ease of reference:

- VCRA Guide - Compiled PDF

- Figure 1 - VCRA Process Diagram

- Attachment A - Checklist

- Attachment B1 - Access Consent

- Attachment B2 - Implementation Consent

- Attachment B3 - Combined Consent

- Attachment C - Site Conceptual Exposure Model

- Attachment D1 - Alternative Comparison Narrative

- Attachment D2 - Alternative Comparison Table

- Attachment E - Model Institutional Controls

- Attachment F - ERCLs Example

Two paper copies and a CD or flash drive containing a modifiable electronic format copy and a compiled searchable PDF version of Voluntary Cleanup Plans should be submitted via a parcel delivery service capable of tracking package delivery to DEQ's physical street address (not mailing address) as follows:

Moriah Bucy, VCRA Coordinator

DEQ - Waste Management & Remediation Division

1225 Cedar Street

Helena, MT 59601

(406) 444-6366

What Is Groundwater Remediation/Water Quality Act (WQA) Program?

The Water Quality Act (WQA) Program is responsible for oversight of investigation and remediation at sites contaminated with petroleum, metals, salts, pesticides, and solvents. Sites range from small to large in scale and are ranked as maximum, high, medium, or low priority, as referred, or as in operation and maintenance status.

WQA Legislation

The Water Quality Act Program (Groundwater Remediation Program) uses the following parts of the Montana Water Quality Act:75-5-101 et seq., MCA. The program uses the following Administrative Rules of Montana:ARM 17.30.1001, 1005-1007, 1010-1011, and 1045 and ARM 17.30.601 et seq.

WQA History

In 1996, due to the reorganization of the Montana Department of Environmental Quality (DEQ), the former Water Quality Division and Groundwater Program were disbanded. Long-term groundwater remediation sites not associated with permitting, underground storage tanks, or Comprehensive Environmental Cleanup and Responsibility Act (CECRA-State Superfund) were transferred to the DEQ Remediation Division (now the Waste Management & Remediation Division). These long-term sites range from petroleum tanker truck wrecks to catastrophic petroleum pipeline ruptures to pesticide sites to dry-cleaning facilities. The former Groundwater Program sites, along with any new sites, now reside in the Contaminated Site Cleanup Bureau, State Superfund Unit, Groundwater Remediation Program. Groundwater Remediation Program sites are regulated pursuant to the Montana Water Quality Act (WQA) or the Montana Agricultural Chemical Groundwater Protection Act (ACGWPA).

The WQA Process

Sites regulated under the WQA (contained in 75-5-101 et seq., MCA) are addressed by the Groundwater Remediation Program. These sites typically require long-term soil, surface water, and/or groundwater remediation and monitoring. This program addresses sites that are not addressed by the Leaking Underground Storage Tank Program, CECRA Program, various permitting programs, or other state authorities.

The Groundwater Remediation Program works cooperatively with the Department of Agriculture when pesticides impact groundwater. The Montana Agricultural Chemical Ground Water Protection Act regulates investigation and cleanup of sites contaminated with agricultural chemicals. The Program uses the following parts of the Montana Agricultural Chemical Ground Water Protection Act:

- Statute: 80-15-101 through 108, 110, 201-203, 211, 213(2),217(1), 301, 302(2)(a)(i), 402, 403(1) through (2)(a)(i)(ii), 411(5), MCA

- Rules: ARM 4.11.101, 203(2), 304(2), (3), 402, 905, 1112-1117

Current WQA Facilities/WQA Priority Lists

Currently, the Groundwater Remediation Program is addressing the sites listed on the "WQA Priority List" available sorted by Facility Name, City, or County.

The WQA Priority List is updated semi-annually and is available in three formats:

- WQA Priority List organized by Site in pdf format

- WQA Priority List organized by City in pdf format

- WQA Priority List organized by County in pdf format

DEQ's Groundwater Remediation Program Contact

Laura Alvey

DEQ - Waste Management & Remediation Division

PO Box 200901

Helena, MT 59620-0901

(406) 444-0212

General Requirements for WQA Site Work Plans

The following are general requirements for work plans prepared for WQA sites, and are not meant to be inclusive for all sites:

- maps of site showing general area of release, detailed map of release area showing topography, watershed features, structures, etc.;

- summary of the site, including how release/contamination occurred or was discovered, description of cleanup/remediation activities at the site, details of individuals and parties involved, other pertinent information;

- detailed description of proposed future activities at the site including excavation and other remediation activities, well drilling and sampling, soil sampling, analytical tests to be run on samples; and

- schedule of activities at the site.

General Requirements for WQA Site Reports

The following are general requirements for reports prepared for WQA sites, and are not meant to be inclusive for all sites:

- maps of site showing general area of release, detailed map of release, potentiometric-surface maps that show groundwater elevation and flow, structures, and a plume map for each sampling event which shows (at a minimum) isopleth lines depicting the Required Reporting Value and the DEQ-7 Standard for the contaminants driving cleanup;

- summary of the site including how release/contamination occurred or was discovered, description of cleanup/remediation activities at the site, details of individuals and parties involved, other pertinent information;

- detailed description of work done at the site including who/what/when/where/how and should include sampling and analytical work;

- figures and tables that summarize results;

- a detailed discussion of the results;

- conclusions and recommendations;

- all analytical results accompanied by the following: chain of custody papers; a description of Quality Assurance/Quality Control information including holding times and temperatures, sample preservation, sample validation, any analytical problems, etc.;

- raw data; and

- review of potential receptors within a 1/4 mile radius and/or a 1/2 mile radius. This review is especially critical when the release has the potential to impact drinking water.

Supporting Documents and Reports

- Water related Notices, Permits, and Authorizations

- Spill Reporting

What Is CALA?

The Controlled Allocation of Liability Act (CALA) is a voluntary process that allows potentially liable persons (PLPs) to petition for an allocation of liability as an alternative to the strict, joint and several liability provisions included in CECRA. CALA provides a streamlined alternative to contribution litigation that involves negotiations designed to allocate liability among persons involved at facilities requiring cleanup, including bankrupt or defunct persons. Cleanup of these facilities must occur concurrently with the CALA process and CALA provides the funding for the orphan share of the cleanup. Since CECRA cleanups typically involve historical contamination, liable persons often include entities that are bankrupt or defunct and not affiliated with any viable person by stock ownership. The share of cleanup costs for which these bankrupt or defunct persons are responsible is the orphan share. The Department represents the interests of the orphan share.

CALA Legislation

The Montana Legislature added the Controlled Allocation of Liability Act (CALA; §§ 75-10-742 through 751, Montana Code Annotated (MCA)) to the Comprehensive Environmental Cleanup and Responsibility Act (CECRA; §§ 75-10-701 through 757, MCA), the state Superfund law, in 1997. The Department administers CALA including the orphan share fund it establishes.

The CALA Process

CALA was designed to be a streamlined, voluntary allocation process. For facilities where a PLP does not initiate the CALA process, strict, joint and several liability remains. This flowchart outlines the basic CALA process. The flowchart does not include some details like the additional fifteen days the PLPs have to designate a lead person if the Department rejects their original choice. However, the flowchart does provide all the major steps in the CALA process. The statute provides timelines for a person who has been noticed as being potentially liable as well as any potentially liable person who has received approval of a voluntary cleanup plan to petition to initiate the CALA process. CALA includes fourteen factors to be considered in allocating liability. Based on these factors, causation weighs heavily in allocation, but is not the only factor considered.

Current CALA Facilities

The Department currently has five facilities that have completed allocations under CALA:

The Corbin Flats facility is located just south of Helena, in and near the town of Corbin, in Jefferson County.

The S&W Sawmill facility is located in Darby, south of Hamilton, in Ravalli County.

The CMC Asbestos Bozeman facility is located in downtown Bozeman (Gallatin County).

The Joslyn Street Tailings facility is located in Helena (Lewis and Clark County).

The Blackfoot Post Yard facility is located in Lincoln (Lewis and Clark County).

The Orphan Share Fund

The orphan share fund is a state special revenue fund created from a variety of sources. The legislature has allocated funds from the resource indemnity and groundwater assessment taxes and from the oil and natural gas production taxes.

The lead PLP can request reimbursement once it completes the final remedial investigation report and again after it completes the final feasibility study report. Reimbursement is limited to those eligible costs incurred by the lead PLP for the preparation of these reports. The lead PLP can also request reimbursement for eligible costs once all remedial actions, except for operation and maintenance are complete. Reimbursement is limited to the orphan’s share of actual documented remedial action costs incurred after the date of the CALA petition.

If the lead PLP demonstrates a financial hardship, the Department may allow the submission of claims and may reimburse the claims prior to the completion of remedial actions.

State Superfund Contacts

Main Number

(406) 444-6444

Fax Number

(406) 444-6783

Mailing Address

PO Box 200901

Helena, MT 59620-0901

State Superfund Section Supervisor

Moriah Bucy (406) 444-6366

Site Response Section Supervisor

Hannah McDermott (406) 444-6578

Env Science Specialist

Laura Alvey (406) 444-0212

Env Science Specialist

Kate Fry (406) 444-6426

Env Science Specialist

Robert Roll (406) 444-6438

Env Science Specialist

Dan Norris (406) 444-6417

Env Science Specialist

Heather Foslund (406) 444-6745

Env Science Specialist

Abby Nathlich (406) 444-6773

Env Science Specialist

Ruby Hopkins (406) 444-6479

Env Science Specialist

Mathew Erickson (406) 444-6545

Env Science Specialist

Kyle Groves (406) 444-6567

Frequently Asked Questions

Will DEQ compensate me for contamination on my property that was caused by someone else?

Neither the Comprehensive Environmental Cleanup and Responsibility Act (CECRA), the Water Quality Act (WQA), or the Montana Underground Storage Tank Act provide for compensation of property owners for contamination on private property. Rather, these statutes are focused on protection of public health, safety, and welfare and the environment by requiring cleanup of contaminated property. However, if a petroleum release is eligible for reimbursement through the Petroleum Tank Release Compensation Fund, then some compensation may be available; see Petroleum Tank Release Compensation Board website for more information.

Is there an example of data validation guidelines that I can use?

Yes, view an example of a data validation guidelines used by the DEQ. (This is an Adobe fillable PDF form that will not download like other PDFs. To access this form, please save the form to your local computer and open the form from the computer using the free Adobe Reader or other Adobe software.)

What data validation and QA/QC information should be summarized in the environmental report text?

While it is not necessary to restate the entire data validation report, the following information is typically summarized in the data quality section of the document to assist with determining data usability. The information that will be summarized is intended to assist the reader in understanding the precision, accuracy, representativeness, comparability, completeness, and sensitivity (PARCCS) of the data collected.

- Identify the laboratory(ies) that performed the analyses.

- Identify if there were any lab issues1. Specifically, explain if there were problems with the following:

- results summary reports

- detection limits not met/not as low as originally planned

- holding times exceeded

- lab methods that differ from the methods planned

- method detection limits that exceed screening levels

- issues with lab control or QA/QC samples (e.g., method blanks, lab control spike, lab control spike duplicate, matrix spike, matrix spike duplicate, surrogate recovery, lab duplicate, continuing calibration verification reports, etc.)

1If there were no laboratory issues, it is helpful to state there were no laboratory issues identified.

- Identify if there were any field issues2. Specifically, explain if there were problems with any of the following:

- the chain-of-custody forms (incomplete, not signed, etc.)

- sample receipt checklist (sample temperature outside of acceptable limits, samples not properly preserved, excess headspace in volatile organic compound samples, samples damaged or missing, any other physical conditions relating to the samples that might adversely affect the analytical results)

- number of samples collected versus number planned

- contamination detected in field blanks/equipment blanks/trip blanks

2If there were no field issues, it is helpful to state there were no field issues identified.

- For any lab or field issues, state what corrective measures have been implemented to minimize future issues.

- If any split samples were collected, then discuss the comparison of the split sample results with the natural sample results. It is helpful to state if no split samples were collected.

- If any duplicate samples were collected that have not previously been discussed in a data results section, then discuss the duplicate results with the natural sample results and identify the percent difference (if site-specific data quality objectives exist for that measurement). It is helpful to state if no duplicate samples were collected.

- Affirm EPA data validation qualifiers were applied by the data validator and are included when data are presented in the text, tables, and figures. EPA data validation qualifiers include:

- J: Estimated concentration

- J+: The result is an estimated quantity, but the result may be biased high.

- J-: The result is an estimated quantity, but the result may be biased low.

- UJ: Estimated reporting limit

- U: Evaluated to be undetected at the reported concentration

- JB: Estimated concentration due to blank contamination

- X: Incomplete Chain-of-Custody

- R: Rejected, Data not usable

- NJ: Tentative identification and estimated concentration

- Present the relative percent difference calculated for field duplicates.

- State the number of sample results reported for the various media and identify the number of rejected results.

- Calculate the completeness of the sample event and clarify if it meets the data quality objectives for the project/event (i.e., 20 samples were planned, but 1 sample was not collected because the well could not be located – therefore, the completeness is 95%). Some people also report the amount of valid data obtained compared to the number of valid measurements that were expected.

- Summarize the usability of the data for the intended purpose.

Is there a list of commonly used acronyms used by the State Superfund Unit?

The State Superfund Unit Acronym List provides a list of commonly used acronyms.

Does the State Superfund Unit have map/figure preparation guidance?

The State Superfund Unit Map Guidance provides general guidance applicable to all maps/figures submitted, as well as specific guidance for the following types of maps/figures: facility location, facility plan-view, sample locations (for all media), potentiometric surface, geologic cross-sections, soil contamination, groundwater contamination, separate phase (free product), and facility contaminant affected area.

What does a feasibility study work plan or report usually contain?

The feasibility study (FS) process consists of the development and screening of remedial alternatives or cleanup options and a detailed analysis of a limited number of the most promising options to establish the basis for a remedy selection decision. A range of viable alternatives are developed that meet the remedial action objectives developed during scoping and refined as the FS progresses. Please see the Final Feasibility Study Report - June 2008 for an example report.

Please see the Feasibility Study Guidance for DEQ’s guidance for facilities addressed under the Comprehensive Environmental Cleanup and Responsibility Act (CECRA). In addition, please see the following links for examples mentioned in the Feasibility Study Guidance:

EXAMPLE 01 - Receptors With Risks Table

EXAMPLE 02 - Surface Soil Lead Concentrations Extent Figure

EXAMPLE 03 - Groundwater Exceeding Cleanup Levels Extent Figure

EXAMPLE 04 - Initial Alternatives Screening Table (IAST)

EXAMPLE 04 - IAST (modifiable)

EXAMPLE 05 - Environmental Requirements, Criteria, or Limitations (ERCLs) Table (Modifiable)

EXAMPLE 05 - ERCLs Table

EXAMPLE 06 - Cost Estimate A Table

EXAMPLE 06 - Cost Estimate B Table

EXAMPLE 07 - Comparative Analysis of Alternatives Text

EXAMPLE 08 - Comparative Analysis of Alternatives Table

EXAMPLE 09 - Conceptual Design of Alternatives

What does a remedial investigation work plan or report usually contain?

Please see the Remedial Investigation Example Scope of Work for an example remedial investigation (RI) scope of work for facilities addressed under the Comprehensive Environmental Cleanup and Responsibility Act (CECRA). Please see the Milwaukee Roundhouse Remedial Investigation Report - June 2015 for an example RI report.

For CECRA facilities in remedial design, are there examples of what should be included in a 30% (Basis of Design), 50%, 90%, or 100% Design Document?

Please click on the link Design Document Components to find examples of the information that should be contained in design documents for facilities addressed under the Comprehensive Environmental Cleanup and Responsibility Act (CECRA).

How does one go about doing a voluntary cleanup?

The purposes of the Voluntary Cleanup and Redevelopment Act (VCRA) are to provide for the protection of the public health, welfare, and safety and of the environment and to foster the cleanup, transfer, reuse, or redevelopment of facilities where releases or threatened releases of hazardous or deleterious substances exist. VCRA is further intended to permit and encourage voluntary cleanup of facilities where releases or threatened releases of hazardous or deleterious substances exist by providing interested persons with a method of determining what the cleanup responsibilities will be for reuse or redevelopment of existing facilities. VCRA is meant to encourage and facilitate prompt cleanup activities, eliminate impediments to the sale or redevelopment of facilities where releases or threatened releases of hazardous or deleterious substances exist, and minimize administrative processes and costs.

The complete VCRA guide is located in the Programs section of the SSU website under "Voluntary Cleanup (VCRA)" and the individual components are also available there for ease of use/reference. The VCRA guide covers both the Environmental Assessment and Remediation Proposal components required under VCRA. The guide also contains a checklist to assist applicants in preparation of the required documents, provides explanations/example language, and provides a suggested format for voluntary cleanup plans (VCPs). The primary target audience for this guide is the qualified environmental professional who is preparing the VCP. However, the guide is also designed to provide information to all applicants or potential applicants regarding the VCRA process.

How do you get a facility removed from the CECRA List?

ARM 17.55.114 identifies the delisting process and there are a number of ways in which a facility on the CECRA Priority List can be delisted. The most common ways are to address the facility either through the CECRA process or through VCRA. A description of the CECRA process is available under the “Programs/State Superfund (CECRA)” drop down menu and information about VCRA is available under the “Programs/Voluntary Cleanup (VCRA)” drop down menu.

Do I need to treat emissions from remediation systems?

The State Superfund Unit (SSU) generally requires treatment of effluent vapor associated with remediation systems that extract contaminated vapors from the subsurface and release the vapor to the atmosphere. However, effluent vapor discharge from these extraction systems can be modeled as outlined in SSU's Effluent Vapor Modeling Guidance to evaluate/demonstrate that discharge of effluent vapor without treatment is protective of human health and the environment.

How do I demonstrate that backfill/borrow material is clean?

Backfill/borrow material to be used at State Superfund Unit facilities needs to be adequately characterized to demonstrate that the material does not contain contaminants at concentrations greater than established screening or cleanup levels. Please see How do I determine borrow material is clean? for additional details (note this information is also presented in the SAMPLING FAQs).

What is considered surface soil?

When addressing contaminated facilities, DEQ considers surface soil to be anything from 0-2 feet below ground surface (bgs).

How do I determine if I have a contaminant of potential concern in soil?

For initial evaluation of contaminants of potential concern, please refer to the “SAMPLING” FAQs; see also the Soil Screening Process Flowchart. Additional information for all media can be found under the “Contaminant Screening Resources” section at the bottom of the State Superfund Unit webpage.

How should moisture data be reported for soil samples?

All soil and sediment data should be reported on a dry-weight basis and moisture percentage should also be determined and reported on the laboratory data reports. Please see the FAQ below on dry-weight conversion.

How is the as-received (wet-weight) result converted to dry-weight for soil samples?

The dry-weight is converted from wet-weight by the following formula:

Dry Weight Result = As-Received Result/(1-% moisture)

Example:

If you have a TEH value of 300mg/kg, and a moisture of 14%, the calculation would be:

300mg/kg /(1-0.14) = 349 mg/kg dry weight

How do I take into account background concentrations of metals in soils?

Metals are naturally occurring in the environment. If metal concentrations exceed screening levels or you suspect they may exceed screening levels, it is appropriate to collect facility-specific background samples from unimpacted areas that are representative of natural conditions. You may also use the Background Metals Table 4-4 as screening levels for background inorganic concentrations in surface and subsurface soils. In some cases, background concentrations may exceed screening levels. In that case, background concentrations may be used in place of screening levels. Consultation with DEQ is recommended.

What are appropriate sampling depths for surface soils?

First, it is important to consider how the contamination was released and what information is needed to evaluate risks and cleanup options. As a general rule, samples are collected from 0-6 inches below ground surface (bgs) in source areas and from 0-2 inches bgs in areas of aerial deposition. Additional sampling at discrete intervals should be conducted from 0-2 feet bgs in order to determine how much of the soil profile is contaminated. Typically, compositing the entire 0-2 feet zone does not provide the information needed meet most project goals. Consultation with DEQ is recommended.

What depths of contamination need to be evaluated for a construction/excavation worker scenario?

Construction workers or those excavating soil are expected to be exposed to both surface (0-2 feet below ground surface (bgs)) and subsurface (2-10 feet bgs) soil. Therefore, it is appropriate to evaluate construction worker exposure to both surface and subsurface soils. If cleanup levels protective of construction/excavation workers are lower than those for other surface soil receptors, the lower cleanup levels could also be applied to surface soil. For additional information please see the Risk Assessment FAQs.

Do I need to cleanup subsurface soils greater than 10 feet if there is no leaching to groundwater or vapor intrusion issues?

In addressing the direct contact risk to the construction/excavation workers at contaminated facilities, remediation of subsurface soil to depths of 10 feet is typically necessary. However, there are some sites where contamination extends deeper than 10 feet and there may be situations where future building at the site could result in footings or foundations greater than 10 feet. In order to ensure protectiveness for direct contact as well as to provide notice to future purchasers of the property, a site with contamination left in place deeper than 10 feet may need an institutional control to limit excavation to 10 feet. (The other option is to remediate subsurface soil to depths greater than 10 feet.) However, the placement of an institutional control does not address those facilities with leaching to groundwater or vapor intrusion considerations.

Why do I have to compare soil sample results to residential screening or cleanup levels when the site is an industrial facility? What happens if the site meets industrial but not residential screening or cleanup levels?

When addressing CECRA facilities, soil concentrations are screened against EPA residential and industrial regional screening levels or site-specific residential and commercial industrial cleanup levels. As part of selecting the final remedy, DEQ will determine “reasonably anticipated future uses” for the facility and what cleanup levels apply.

When collecting surface soil samples for metals analyses, why do I need to sieve the soils and what size sieve do I use?

Previous site investigations across the country have demonstrated a tendency for lead contamination to be concentrated in the finer (dust sized) fraction of soil. It is also from this size fraction that most exposure to humans occurs. DEQ evaluated sieved vs. unsieved samples in its Background Concentrations of Inorganic Constituents in Montana Surface Soils and determined that most often the finer fraction contains higher metals concentrations. Therefore, at facilities where metals are likely to be contaminants of concern, analysis of the finer fraction should be performed to appropriately evaluate risks to human health. Samples may either be sieved in the field or in the laboratory.

The determination of which sieve size is appropriate for the sampling event is based on the site, historic sampling and how the data will be used. Historically, soil samples that were collected for risk assessment purposes were processed with a No. 60 sieve (250 µm) to obtain the fine fraction for sampling. In 2016, the US EPA published information recommending a No. 100 (<150 µm) sieve be used based on evidence showing that dermally adhered soil is mostly fine particle fractions (especially representative of the size particles that adhere to children’s hands). In addition, the In Vitro Bioaccessibility Assays for lead and arsenic should be done using the <150 µm fraction (EPA, 2021). Please ensure that site-specific sampling procedures are discussed with DEQ’s project officer prior to sampling.

For sites with historic soil data sieved to 250 microns (#60 sieve):

The EPA Technical Review Workgroup has emphasized that in consideration of evidence, the use of a No.100 sieve for <150 µm particles (in place of a No. 60 sieve for <250 µm) should be implemented going forward for evaluating soil contaminant concentrations. However, there are instances where evaluation of historical soil data sieved to 250 µm may be necessary. In these cases, please note the difference in sieve sizes in the uncertainty section of the risk assessment or in the data discussion sections of other reports and describe how this difference may or may not affect the results of the evaluation being presented.

For initial characterization of sites:

During an initial site characterization, a portion of the samples could be laboratory analyzed in both sieved and unsieved (bulk) form, with a representative number of samples laboratory-analyzed in both forms. The samples selected for both analyses should account for different sources, lithology, or other characteristics that could influence the ratio between sieved and unsieved sample concentrations. If possible, samples analyzed in both forms should be collected from areas of low, medium, and high levels of contamination (XRF analysis may be a useful tool for some metals). The frequency of analysis of both types of samples should be 100% of samples in samples sets of less than 20 samples, at least 20 bulk samples in sample sets of 20 – 100 samples, and 20% of the bulk samples in sample sets greater than 100 samples. An enrichment ratio of sieved to unsieved analysis can be calculated for each sample, followed by a 95% upper confidence level (UCL) on the mean of the ratios. The enrichment ratio may then be applied to historic, current, and future bulk samples collected for characterization or confirmation sampling without the need for further sieved sampling.

For More Information, Please see the following guidance documents:- EPA Recommendations for Sieving Soil and Dust Samples at Lead Sites for Assessment of Incidental Ingestion, 2016

- EPA Guidance for Sample Collection for In Vitro Bioaccessibility Assay for Arsenic and Lead in Soil and Applications of Relative Bioavailability Data in Human Health Risk Assessment, 2021

- Superfund Lead-Contaminated Residential Sites Handbook

For information on screening levels for lead in soil, please refer to the DEQ Lead Screening memo, the Screening FAQ (under Sampling FAQ category) or the Soil Screening Flowchart available under the Soils portion of the Contaminant Screening Resources portion of the State Superfund website.

For screening purposes, can an XRF be used instead of laboratory analysis for metals soil samples and how should the data be evaluated?

If XRF data is collected, the size of the data set needs to be considered. To ensure the quality and reliability of the XRF results, for sample sets of less than 10 samples both XRF and collection of laboratory samples is required for 100% of the samples. For sample sets of 10-100 samples, at least 10 samples are required to have laboratory analysis and 10% of the samples in sample sets greater than 100 samples are required to have laboratory analysis (this does not preclude the evaluation of 20% of the samples collected for the lead finer fraction analysis explained above). DEQ recommends that samples selected for laboratory analysis be focused around data that is near the action level, with a minimum of 25% of the XRF high and low range concentration samples sent to the laboratory for analysis. For smaller data sets, laboratory analysis only may be more appropriate. The relative percent difference (RPD) of each XRF/laboratory sample pair should be calculated. The average RPD of the XRF/laboratory sample pairs should not exceed 35% (per EPA National Functional Guidelines for Inorganic Data Review, October 2004). A graph showing the correlation between the XRF and laboratory results should be provided and the correlation coefficient for the results should be 0.7 or greater for the XRF data to be considered screening level data (per EPA Method 6200 [XRF]). A discussion that identifies the factors that may affect the strength of the correlation and why it is or is not indicative of a strong relationship between the two data sets should also be provided (e.g., false negatives or positives, outliers, correlated residuals, XRF sample interference, elevated detection limits, bias).

The project-specific SAP/QAPP should cover XRF data collection, XRF and lab quality control requirements (including XRF calibration), collection of laboratory samples, comparison of XRF to laboratory data, and a detailed description of the XRF/laboratory data correlation, as described above. The XRF/laboratory data comparison and correlation should also be discussed as part of the overall data quality for the investigation.

Please see the following documents: Montana Vapor Intrusion Guidance Document, and the Montana Typical Indoor Air Concentrations Document.

Please also see Effluent Vapor Modeling Guidance if a remediation system is planned/installed.

Download the following soil vapor intrusion FAQ as a PDF: (148K)

What is soil vapor intrusion?

The phrase "soil vapor intrusion" refers to the process by which volatile chemicals move from beneath the ground into the indoor air of overlying buildings.

Soil vapor, or soil gas, is the air found in the spaces between soil particles. Because the air pressure inside may be lower than in the soil, this vapor may enter buildings through cracks in slabs or basement floors and walls, and through openings around sump pumps or where pipes and electrical wires go through the foundation. Heating, ventilation or air-conditioning systems may reduce the air pressure inside, drawing soil vapor into buildings.

Chemicals that readily evaporate or vaporize are called "volatile chemicals." Volatile chemicals include volatile organic compounds (VOCs), which includes, but is not limited to, benzene (typically found in gasoline) and tetrachloroethylene (typically found in dry cleaners or degreasing operations). Subsurface sources of volatile chemicals may include contaminated soil and groundwater, broken pipes, or buried wastes. If soil vapor is contaminated and enters a building as described above, the air quality inside the building may be affected.

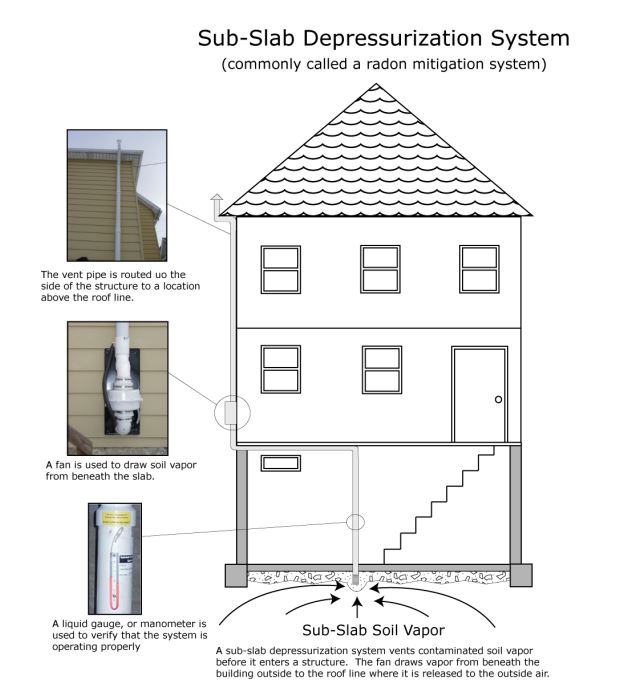

When contaminated vapors are present nearby or under the foundation of the building, vapor intrusion is possible. Soil vapor can enter a building whether the building is old or new, and whether the building has a basement, a crawl space, or is on a slab (as illustrated in the figure below).

Soil Vapor Intrusion Image

Figure courtesy NYSDOH, October 2006

How do we screen contaminated vapors?

For initial screening of contaminants of concern, please refer to the Sampling FAQs for guidance.

Which analytical method do I use to analyze for vapors in soil gas or indoor air?

EPA method TO15 typically provides the appropriate detection limits that are needed to determine of volatile chemicals pose an unacceptable risk to humans.

How could I be exposed to chemicals through soil vapor intrusion?

Humans can be exposed to contaminated soil vapor when vapors from beneath a building are drawn through cracks and openings in the foundation and mix with the indoor air. These vapors may be inhaled along with the indoor air.

In general, inhaling a volatile chemical does not necessarily mean that a person will experience health effects. Whether or not a person experiences health effects depends on several factors, including the length of time a person is exposed, the number of times a person is exposed, the toxicity of the volatile chemical, and person’s sensitivity to the chemical.

Is contaminated soil vapor the only source of volatile chemicals in my indoor air?

There are other potential sources of contaminants in indoor air. Volatile chemicals may also be found in certain household products such as paints, paint strippers and thinners, mineral spirits, glues, solvents, cigarette smoke, aerosol sprays, mothballs, air fresheners, new carpeting or furniture, hobby supplies, lubricants, stored fuels, refrigerants and recently dry-cleaned clothing.

Indoor air may also become affected when outdoor air containing volatile chemicals enters your home. Volatile chemicals may be present in outdoor air due to their widespread use. Gasoline stations, dry cleaners, and other commercial/industrial facilities are also potential sources of VOCs to outdoor air.

DEQ looked at volatile chemicals in homes that were not located near known contamination. The results of the study are summarized in the Montana Typical Background Indoor Air Concentrations document available on the Resources page.

What should I expect if indoor air samples are collected in my home?

You should expect the following:

Indoor air samples are generally collected from the lowest-level space in a building, such as a basement. They are often collected during cold weather when the building is heated and the ground is frozen. Indoor air samples may also be collected from the first floor of living space, or any other area of potential concern. Indoor air samples are used to determine if vapors are inside buildings.

Sub-slab vapor and outdoor air samples are usually collected at the same time as indoor air samples to help determine where volatile chemicals may be coming from (indoor sources, outdoor sources, and/or beneath the building).

Some sampling may be performed during warmer weather. For example, soil gas or sub-slab vapor samples without indoor air or outdoor air samples may be collected to identify buildings and areas where comprehensive sampling is needed during the heating season.

An indoor air quality questionnaire and building inventory will be completed with your input. The questionnaire includes a summary of the building's construction characteristics; the building's heating, ventilation and air-conditioning system operations; and potential indoor and outdoor sources of volatile chemicals. The building inventory describes products present in the building that might contain volatile chemicals. These products may be temporarily removed from the building while it is being sampled with homeowner consent.

If my home was identifies for sampling, should I do anything different than normal at home during or before the sampling?

At least 48 hours prior to and during the collection of the indoor air sample (which takes 24 hours), please take the following actions to minimize background concentrations of VOC's:

Try to avoid opening windows or keeping doors open.

Avoid operating ventilation fans or air conditioning if possible.

Please avoid using air fresheners or odor eliminators.

Please do not smoke indoors.

Please do not use paint, solvents, or varnishes.

Please do not use cleaning products such as bathroom cleaners, furniture polish, appliance cleaners, all-purpose cleaners, floor cleaners, or gun cleaners.

Please try to minimize the use of cosmetics such as hair spray, nail polish, nail polish remover, perfume, cologne, etc.

Please do not apply pesticides.

Please do not store containers of gasoline, oil, petroleum-based or other solvents within the house or use them in an attached garage.

Please do not operate or store automobiles in an attached garage if possible.

It is important to note that many building materials contain VOCs, such as plywood flooring, latex paint, sheet vinyl flooring, and new carpeting, among others. Obviously, it is not practical to remove these potential indoor sources of VOCs from homes. However, removing all identified household products which may contain VOCs and adhering to this list of steps to take prior to and during sampling will help minimize the background levels of VOCs in your house or business.

What happens if soil vapor contamination is found to be affecting my home or work place?

Depending on the investigation results, DEQ may require additional sampling or mitigation, in addition to requiring cleanup of the subsurface sources. Additional sampling would be performed to determine the extent of soil vapor contamination and to verify questionable results. Mitigation is action that is taken to minimize exposures to indoor air contamination while cleanup is occurring. Mitigation may include sealing cracks in the building's foundation and installing a sub-slab depressurization system beneath the building (similar to a radon mitigation system), or other options that would limit vapors inside buildings.

What types of mitigation systems are available for buildings?

A sub-slab depressurization system essentially prevents vapors beneath a slab from entering a building. A low amount of suction is applied below the foundation of the building and the vapors are vented to the outside (see figure below). Mitigation systems are inspected to insure that they are effective and that they do not cause any “back-drafting.” The system uses minimal electricity and should not noticeably affect heating and cooling efficiency.

Sub-Slab Depressurization System

Figure courtesy NYSDOH, October 2006

Vapor Barriers

A vapor barrier is a sheet of geomembrane or strong plastic that is placed beneath a building. It may be more appropriate for new construction, but may also work for buildings with crawl spaces. It is difficult to retrofit existing buildings with a vapor barrier. However, some concrete floors may be able to be sealed with a substance that my limit the movement of vapors into the building.

Improved Heating , Ventilation, and Air Conditioning (HVAC) Systems

In some situation, HVAC systems may be adjusted to increase the pressure indoors relative to the pressure beneath the buildings slab. This approach is typically useful for larger buildings.

Does DEQ/SSU have guidelines for low-flow sampling?

Please refer to the Groundwater Sampling Guidance document.

How can I dispose of purge water from monitoring wells at my facility?

Untreated purge water is the water removed from a monitoring well before a groundwater sample is collected. Purge water may be allowed to infiltrate to the subsurface by discharging it on the ground next to the well under certain conditions. Purge water is considered a waste and the discharge of wastewater is regulated under the requirements of the Montana Water Quality Act (75-5-101, et seq. MCA) and the rules that have been adopted to implement the act.

Purge water may not be discharged on the ground if the discharge will result in the spread of contamination. The discharge of unaltered purge water to the contaminated water-bearing zone from which it originated does not require a Ground Water Pollution Control System discharge permit. It must be reasonably expected that the purge water will return to the same aquifer zone where the purge water originated. The guidelines for purge water disposal are further clarified in the purge water disposal flowchart. If the answer to any of the questions within the flowchart is “Yes” purge water may not be disposed on the ground surface and you may need to work with your DEQ contact to determine appropriate disposal options.

How can I dispose of wastewater generated or produced at my facility?

Discharges of wastewater from sources other than purge water from groundwater monitoring wells are generally administered by the DEQ’s Permitting and Compliance Division’s Water Protection Bureau. Discharge of wastewater to a municipal wastewater treatment plant requires authorization from the municipal wastewater treatment operator. Please contact the Water Protection Bureau at (406) 444-3080. Call: (406) 444-3080 prior to discharging wastewater to determine if a permit is necessary.

What are the requirements for installing, surveying, and abandoning monitoring wells?

The Montana Department of Natural Resources and Conservation (DNRC) has adopted rules governing the installation and abandonment of monitoring wells in Montana. Construction standards for monitoring wells are found in Administrative Rule of Montana (ARM) 36.21.801 et seq. and includes requirements for construction materials, installation of seals, prevention of contamination by equipment, and site protection and security. The regulations also require that a monitoring well constructor licensed by the Montana Board of Water Well Contractors prepare a monitoring well report form for each monitoring well drilled. The monitoring well constructor must supply copies of the report to the monitoring well owner and DNRC within 60 days of completing the well and must also retain a copy as a record in the constructor's files.

In addition, Montana Code Annotated (MCA) § 85-2-516 requires that, within 60 days after any well is completed, the driller must file a well log report with the Montana State Bureau of Mines and Geology. The well log report must be filed on a form specified by DNRC, which includes identifying a location for the well using at least two methods as specified on the form.

An initial survey of groundwater monitoring well elevations must be completed by a licensed surveyor or professional engineer registered in the State of Montana in accordance with MCA § 37-67-301 et seq. and ARM 24.183.101 et seq. Survey results must provide an accuracy of plus or minus 0.1 foot horizontally and plus or minus 0.01 foot vertically. The vertical control datum used to determine the elevation of the well must be the North American Vertical Datum of 1988 (NAVD 88), which should be referenced to a nearby United States Geological Survey (USGS), or equivalent, benchmark.

At CECRA facilities, latitude and longitude coordinates reference the State Plane NAD83 HARN Coordinate System, which should also be referenced to a nearby USGS, or equivalent, horizontal control mark.

ARM 36.21.810 provides that “[w]ells which have not been monitored for more than 3 years shall be deemed abandoned unless written permission is obtained from the board [of water well contractors] to maintain the well.” Standards for abandoning monitoring wells is also provided in this regulation.

Additional regulation regarding Monitoring Well Construction Standards can be found in the ARM 36.21.8.

Can I do a risk assessment to close a site when the site has an exceedance of Montana numeric water quality (DEQ-7) standards?

DEQ-7 standards were developed to comply with requirements under the Montana Water Quality Act, the Federal Clean Water Act, and the Montana Agricultural Chemical Ground Water Protection Act and must be used. A risk assessment that provides site-specific cleanup levels may be appropriate for contaminants in soil, but not in groundwater, for contaminants that have DEQ-7 standards. For contaminants without a DEQ-7 standard, see "What are some of the general assumptions for a site-specific groundwater risk assessment/analysis at a CECRA facility?".

What kinds of site-specific data do I need before I can calculate site-specific cleanup levels protective of groundwater or perform other kinds of modeling at a site?

Please refer to the DEQ guidance document "Fate and Transport Modeling - General Field Data Needs".

Do I have to perform a Fate and Transport Analysis?

You have the option to use screening levels as cleanup levels so that a Fate and Transport Analysis is not necessary. However, if you choose to calculate site-specific cleanup levels, DEQ will also require the use of fate and transport modeling of the soil leaching to groundwater pathway to determine a cleanup level for this pathway (please refer to the Fate and Transport FAQ. ) In addition, site-specific cleanup levels require the use of standard EPA human health risk assessment guidance (EPA 1999, 1998a, 1997b, 1992, 1991a-c, and 1989) and/or, as applicable, standard EPA ecological risk assessment guidance (EPA 2000a, 1998b, and 1997a) using assumptions acceptable to DEQ. Please see the Risk Assessment/Analysis section of the FAQs for additional information. It is important to identify as early in the CECRA process as possible if you are going to calculate site-specific cleanup levels, so that the data for fate and transport can be collected during the RI.

Do I have to sample for both total and dissolved metals in groundwater?

At CECRA facilities, DEQ will generally not require that groundwater samples taken from monitoring wells be analyzed for total metals but will continue to require that drinking water wells be analyzed for total metals. Total metals analysis of groundwater from monitoring wells may be needed on a case-by-case basis, as necessitated by special situations (i.e. analyzing background monitoring wells for comparison to drinking water wells). Samples taken from monitoring wells must still meet compliance with other water quality requirements including Montana’s Numeric Water Quality Standards (DEQ-7).

What are the initial screening levels used for determining contaminants of concern?

DEQ has determined that an imminent and substantial endangerment to public health, safety, or welfare or the environment may exist if contaminant concentrations at a CECRA exceed certain risk-based screening levels. Contaminants of concern (COCs) are those contaminants whose concentrations exceed these risk-based screening levels, and therefore require additional evaluation. Contaminants whose concentrations fall below these screening levels will not typically trigger CECRA action.

Groundwater/Drinking Water/Surface Water:

-

Surface water and groundwater concentrations may not exceed the standards provided in the Montana Numeric Water Quality Standards Circular 7 (DEQ-7). Please see the relevant footnote in the DEQ-7 guidance regarding surface water contaminants that must be adjusted for hardness.

-

Drinking water may not exceed the Maximum Contaminant Levels (MCLs), published at 40 CFR 141.11, 40 CFR 141.61, 40 CFR 141.62, 40 CFR 141.63, 40 CFR 141.64, 40 CFR 141.65, and 40 CFR 141.66 (2010).

-

For compounds in groundwater that do not have DEQ-7 standards or MCLs, groundwater risk-based screening levels (RBSLs) from the Montana Tier 1 Risk-Based Corrective Action Guidance for Petroleum Releases (RBCA) document may be used as screening levels.

-

For compounds in groundwater with no DEQ-7 standard, MCL, or RBSL screening level, screen concentrations to the EPA tapwater regional screening levels contained in the most recent Regional Screening Levels (RSL) for Chemical Contaminants at Superfund Sites guidance document.

-

For manganese in groundwater, please perform initial screening with the secondary MCL.

Soils and Sediments:

-

Sediment concentrations will be compared to EPA Region 3 BTAG Freshwater Sediment Screening Benchmarks.

-

Dry-weight soil concentrations will be compared to the applicable direct contact and leaching to groundwater-based screening levels as outlined in DEQ’s Surface and Subsurface Soil Screening Flowchart (pay particular attention to footnotes that provide further guidance). These include Montana-specific Background Threshold Values (BTVs) for metals, direct contact and leaching to groundwater-based soil screening levels (SSLs) contained in the most recent Environmental Protection Agency (EPA) Regional Screening Levels (RSLs) for Chemical Contaminants at Superfund Sites guidance document, and for petroleum compounds in soil, the Risk-Based Screening Levels (RBSLs) provided in the Montana Tier 1 Risk-Based Corrective Action Guidance for Petroleum Releases.

-

The direct contact RSLs take into account ingestion, inhalation, and dermal contact pathways and include residential and industrial exposure. The leaching to groundwater-based SSLs found in the EPA RSL table are based upon either the MCLs or the tap water RSLs. If the DEQ-7 groundwater standard is the same as the MCL, the MCL-based SSL multiplied by a dilution attenuation factor of 10 (the state-specific attenuation factor) may be used. If the DEQ-7 groundwater standard is more conservative than the MCL, the SSL must be recalculated so that it is based upon DEQ-7 groundwater standards and multiplied by a dilution attenuation factor of 10. Please see DEQ’s Soil Screening Flowchart for additional information on how to calculate the SSL based upon DEQ-7 standards.

-

There are two EPA RSL tables, and the difference between them is associated with the non-carcinogenic contaminants screening levels. DEQ’s Soil Screening Flowchart is designed to work with the RSL table based upon a hazard index of 1 (a level which indicates that no adverse non-cancer human health effects are expected to occur for that contaminant). When screening contaminant concentrations to the RSLs, with the exception of lead, adjust all non-carcinogenic levels by dividing by ten. This ensures that, when multiple contaminants are found at a facility that may have the same health effects, cumulative potential health effects are considered. Please see DEQ’s Soil Screening Flowchart for additional information on how DEQ screens all non-carcinogens (except lead) by dividing the RSL screening levels by ten and note specific guidance in related footnotes in the flowchart.

-

Exposure to lead in soils is evaluated in a unique way by calculating potential blood lead levels resulting from exposure to lead in soil in addition to other unavoidable lead exposure pathways like water and food. Therefore, DEQ does not include exposure to lead with the other cumulative non-carcinogenic effects. DEQ determined that screening and cleanup levels in Montana must meet the 5 ug/dl, blood lead endpoint and calculated the applicable screening levels for residential (200 mg/kg) as well as commercial/industrial and construction workers (696 mg/kg). More information can be found in the 'Evaluating Lead in Soil' lead screening memo (also available on the Resources page) and in the DEQ Soil Screening Flowchart and associated footnotes.

-

When screening metals (except for lead; see above) concentrations in surface or subsurface soils, compare contaminant concentrations to the Background Threshold Values (BTVs) presented in Table 4-4 of the Background Concentrations of Inorganic Constituents in Montana Surface Soils Report (full report available on the Resources page). If the BTV is higher than the direct contact RSL divided by 10 (as outlined above), and/or is higher than the applicable EPA SSL, use the BTV as the applicable screening level for the direct contact and/or leaching to groundwater pathways (e.g., arsenic background concentrations are elevated in Montana, so the BTV for arsenic is higher than either the RSL (divided by 10) or the leaching to groundwater-based SSL, so the BTV is used as the screening level for both direct contact and leaching).

-

Indoor Air/Soil Vapor:

-

Indoor air and soil vapor concentrations are compared to the residential air and industrial air screening levels contained in the most recent EPA Regional Screening Levels (RSLs) for Chemical Contaminants at Superfund Sites guidance document.

-

There are two EPA RSL tables, and the difference between them is associated with the non-carcinogenic contaminants screening levels. DEQ’s directions outlined below are intended to work with the RSL table where the non-carcinogenic contaminants screening levels are based upon a hazard index of 1 (a level which indicates that no adverse non-cancer human health effects are expected to occur for that contaminant). When screening contaminant concentrations to the EPA RSLs for air, with the exception of lead, DEQ adjusts all non-carcinogenic levels by dividing by ten. This ensures cumulative potential health effects are considered when multiple contaminants with the same health effects are present at a facility.

-

DEQ developed generic screening levels for the petroleum fractions detected using the Massachusetts Air-Phase Petroleum Hydrocarbons (APH) method but not found in the RSL table. DEQ calculated these screening levels using the same assumptions as those EPA used to calculate the RSLs, except for lifetime, where EPA’s default of 70 years was switched with DEQ’s default of 78 years. As these petroleum fractions are non-carcinogens, DEQ adjusted the target hazard index by dividing by ten to ensure that cumulative potential health effects are addressed (please see related explanation in previous bullet). However, when screening, DEQ also considers the typical indoor air concentrations found during DEQ's 2012 Typical Indoor Air Concentrations Study (available on the Resources page) for the two aliphatic fractions because the typical indoor air concentrations are higher than the calculated residential screening levels, as shown below. Therefore, for these compounds, the typical indoor air concentration can be used in used in place of the residential screening level.

Generic APH Fraction Screening Levels*:

* See DEQ’s February 2025 Air Phase Vapor Intrusion Screening Values Memo for more information and note that only the APH fraction screening levels from Table 1 in this memo should be used. The memo is intended to outline the screening approach for petroleum ONLY sites, not to be used at solvent or mixed contamination sites, because there may be more or different contaminants than assumed.

What are the cleanup levels that should be used?

-

Established generic screening levels: For initial screening of contaminants of concern, please refer to the previous question for guidance.

-

Background levels: DEQ accepts attainment of facility-specific background levels based on samples collected from unimpacted areas representative of conditions at the facility for compounds such as metals. Established literature values for background concentrations may be also proposed. In some cases, background concentrations may exceed screening levels and may, therefore, be used in place of screening levels. However, background concentrations that exceed applicable environmental laws (such as DEQ-7 standards) may necessitate that a facility remain on the CECRA Priority List.

-

Facility-specific adjusted screening levels: The generic screening levels described above may be adjusted based on the number of compounds present at an individual facility to represent the acceptable cumulative cancer risk of less than or equal to 1X10-5 for carcinogens or by the number of compounds and their critical effect/target organs for a total hazard index equal to 1 for non-carcinogens. For example, in the RSL table, RSLs for carcinogenic compounds are based on a 1x10-6 cumulative risk, while DEQ will accept a cumulative risk of 1x10-5. The RSLs for non-carcinogenic compounds can be adjusted in a similar manner to account for multiple compounds that have the same critical effect or target organ.

-

Facility-specific risk-based cleanup levels: DEQ will accept cleanup levels based on a facility-specific risk analysis conducted using standard EPA human health risk assessment guidance (EPA 1999, 1998a, 1997b, 1992, 1991a-c, and 1989) and/or as applicable, standard EPA ecological risk assessment guidance (EPA 2000a, 1998b, and 1997a). For human health, DEQ allows cleanup levels calculated based on cumulative risk levels less than or equal to a total excess cancer risk of 1x10-5 for carcinogens or a total hazard index less than or equal to 1 for non-carcinogens. Ecological risks must be evaluated, and acceptable risk determinations are made on a facility-specific basis. Soil leaching to groundwater pathway must be considered when calculating facility-specific cleanup levels to ensure protection of groundwater (please refer to the Fate and Transport FAQ.) All exposure assumptions must be acceptable to DEQ and are best determined in consultation with DEQ.

What must be included with laboratory analytical sample results reports?

The following items are typically included in a Level III analytical package (depending on the laboratory) and must be included with laboratory analytical results submitted to DEQ:

Results Summary Report Including Surrogate Recovery Data;

Results for soil and sediment samples reported on a dry-weight basis;

Chromatograms (if applicable);

Initial and Continuing Calibration Verification Reports;

Laboratory Control Sample Reports (if applicable);

Laboratory Method Blank Reports;

Laboratory Fortified Blank Reports;

Duplicate Analysis or Matrix Spike/Matrix Spike Duplicate analysis reports;

Field, trip, and rinsate blank reports (if applicable);

Sample ID cross-reference (if applicable);

Chain of Custody Form(s); and

Sample Receipt Checklist.

What is an acceptable grid size for confirmation sampling?

In general, confirmation sampling grids should be 25 feet by 25 feet. However, alternate sampling strategies are considered on a facility-specific basis. For example, it may be appropriate to collect samples along radial lines extending from a known source of airborne contamination. It may also be appropriate to collect samples from larger grids on very large facilities; however, factors like heterogeneity of contamination must be considered in determining grid size.

How do I demonstrate that backfill/borrow material is clean?

Backfill/borrow material to be used at State Superfund Unit facilities needs to be adequately characterized to demonstrate that the material does not contain contaminants at concentrations greater than established screening or cleanup levels. Please see ( How do I determine borrow material is clean?) for additional details.

Why do I have to sample for dioxins when pentachlorophenol contamination is the problem?

Dioxins/furans are created as a by-product during the manufacturing of pentachlorophenol, among other things, and are typically present where pentachlorophenol is found. Both dioxins/furans and pentachlorophenol are considered probable human carcinogens, although dioxins/furans are more carcinogenic at much lower concentrations. For example, pentachlorophenol is generally measured in parts per billion, while dioxins/furans are measured in parts per quadrillion. Therefore, at CECRA facilities, samples should be analyzed for dioxins/furans using EPA Method 8290 if pentachlorophenol is suspected or found to be present.

What are TEQs and why/how do I calculate them for dioxins/furans?

Because dioxins/furans are actually a combination of many different chemical compounds, a toxicity equivalence quotient (TEQ) is calculated to represent the total toxicity for each sample. This TEQ concentration is calculated by adjusting the concentrations of several of the dioxin/furan compounds to account for their toxicity and then adding all of the adjusted concentrations. This totaled concentration (identified as a Total TEQ) is then compared to the appropriate screening level. DEQ requires use of ½ the detection limit for non-detected compounds in the TEQ calculation and has developed a Dioxin/Furan TEQ Calculator for Soil and Water Samples (also available through the Resources page) to assist in the calculation of TEQs. The TEQ calculator includes an example with guidance, as well as a blank version that can be used for calculating TEQs based on site-specific data.

How do I calculate a TEQ for dioxins/furans when the lab qualifies a congener as a "K" or EMPC?

A "K" or estimated maximum possible concentration (EMPC) qualifier from the lab means that interfering substances impacted the determination of which compounds were present in the sample. Therefore, the laboratory must estimate the maximum possible detection of the compound. In the Dioxin/Furan TEQ Calculator "K" or EMPC values are treated as the detection limit (DL) and therefore these values should be included in the DL column.

What happens if there is no analytical method with a low enough detection limit to tell if a sample meets a given standard?